News

- What attentions when using a bottle jack ?Keep the following in mind when using a bottle jack: The base of the jack should be fully supported and as level as possible. When working on soft surfaces, put a sturdy metal plate under the base of the jack for stability. The base of the jack should be fully supported and as level as possible. When working on soft surfaces, put a sturdy metal plate under the base of the jack for stability. Do not try to lift a load more than the rated stroke. If you need to lift the load further, block the load, raise the level of the jack with a sturdy support, and continue the lift REMEMBER: Do not go under a load supported by a bottle jack. After the load has been raised, it should be blocked.

2020 12/21

- How do industrial lifting magnets work?How do industrial lifting magnets work? Most of the work put into each model is focused on the device itself. Electrically activated devices are highly powerful and can lift many tons of metal at once without trouble. Each device consists of a metal core, typically iron, wrapped in an electric coil. During operation, the coil is charged with a burst of electricity and generates an attractive field. The coil is made of copper, though any highly conductive material is also appropriate. During operation, the electrical resistance in the coil generates an incredible amount of heat, which can degrade the device`s power, so insulation is important. The attractive field generated by the coil realigns the atoms in the metal core. Prior to operation, the atoms in the metal are randomly aligned, consisting of what is known as random domains. The electrical current creates a uniformly aligned domain in the metal, greatly amplifying the attractive field. The tightness of the coil and the material used in the metal core are primarily responsible for the device`s working power. Scaling both of these up is what gives industrial lighting magnets their impressive grabbing ability. That means that as electrical power is added to the device, its attractive force also increases. Once the atoms in the metal are completely aligned, increasing the electrical current won`t increase the attractive force. Most models are made so that it is impossible to power the device beyond saturation. The technology is beneficial in that it can easily be turned on and off. It can also be precisely controlled, so there is minimal risk of an accident occurring. With easy to use controls , a technician can quickly increase or decrease the output of the device, making for efficient separation or transport. That is particularly useful in the recycling industry, where separating and pulling out iron or steel scrap is par for the course. Most devices also come with a backup system for safety reasons. The only problem with electrically activated devices is that they are reliant on power to function. If this power is suddenly cut, it can cause a major safety hazard. With a permanent device backup, this isn`t a concern. A permanent device does not require electricity to function and is usually made from metal alloys that have been previously exposed to an attractive field. Even after removing the material from the field, the alloy retains atomic alignment for a long time. These systems, operating in tandem, can provide all of the grabbing force a processing facility could ever need.

2020 04/20

- How Does a Scissor Jack Work?How Does a Scissor Jack Work? Operation A scissor jack is operated simply by turning a small crank that is inserted into one end of the scissor jack. This crank is usually "Z" shaped. The end fits into a ring hole mounted on the end of the screw, which is the object of force on the scissor jack. When this crank is turned, the screw turns, and this raises the jack. The screw acts like a gear mechanism. It has teeth (the screw thread), which turn and move the two arms, producing work. Just by turning this screw thread, the scissor jack can lift a vehicle that is several thousand pounds. Construction A scissor jack has four main pieces of metal and two base ends. The four metal pieces are all connected at the corners with a bolt that allows the corners to swivel. A screw thread runs across this assembly and through the corners. As the screw thread is turned, the jack arms travel across it and collapse or come together, forming a straight line when closed. Then, moving back the other way, they raise and come together. When opened, the four metal arms contract together, coming together at the middle, raising the jack. When closed, the arms spread back apart and the jack closes or flattens out again. Design and Lift A scissor jack uses a simple theory of gears to get its power. As the screw section is turned, two ends of the jack move closer together. Because the gears of the screw are pushing up the arms, the amount of force being applied is multiplied. It takes a very small amount of force to turn the crank handle, yet that action causes the brace arms to slide across and together. As this happens the arms extend upward. The car's gravitational weight is not enough to prevent the jack from opening or to stop the screw from turning, since it is not applying force directly to it. If you were to put pressure directly on the crank, or lean your weight against the crank, the person would not be able to turn it, even though your weight is a small percentage of the car's.

2020 04/22

- How to use your mini electric hoist ?Some details and production ability of the mini electric hoist were introduced in the last post. This one will discuss some usage of the electric hoist. With the civil voltage 220V/110V 50Hz/60Hz single phase and the lifting weight 200kg-1T, it enables the safe lifting freely in the home, garden, restaurant and workshop,simply by pressing a switch. Lifting meters can be adjusted from 10M to 30M according to your demands. There are two ways in using by double hooks or single hook: For example the PA200, 12M mini electric hoist, the wire rope with a cross-section can be used with a guide roller and load hook to lift a maximum load of 200KG to 6M.Without the guide roller , the maximum load is halved but the lifting height is increased to 12M. You really don't need to worry about the safety of this machine. Don't mention the best spareparts of it, there are numerous feathures of it whening using. Please check the insulated emergency switch on the handling, which can stop the hoist immediately. The cooper motor is protected from overheating by a thermostatic switch.The anti-rotation wire rope prevents the load from twisting while it is being lifted. A safety latch on the load hook prevents the load from dropping unintentionally , while an automatic brake is ready to secure the load in any position. The mini hoist also can be used matching with the electric trolley and frame.

2020 04/22

- How many types of crane scale ?Crane scales, wireless crane scales and dynamometers provide safe and reliable weighing and measurement solutions. Supplying crane scales and dynamometers to practically every industry, Crane scale has a wide range of scale classifications: general purpose crane scales, compact crane scales, enhanced crane scales, economical crane scales, smart crane scales, mini crane scales, portable crane scales, heavy-duty crane scales, heat-resistant crane scales, wireless crane scales, dynamometers and wireless dynamometers.

2020 04/22

- How to Use Wire Rope Clips ?Drop forged wire rope clips vs. malleable wire rope clips While wire rope clips are not designed to be used in an overhead lifting situation (swage sleeves should be used instead), drop forged wire rope clips are a heavy duty wire rope clip that can be used for sustaining overhead loads. Examples include guy lines, support lines, scaffolding, etc. Drop forged clips are galvanized, meaning they have a heavy coating of a zinc solution that will hold up to worksite abuse and the elements for a long time. Drop forged steel are excellent for use as guy wire clamps for heavy duty guying applications because they are both strong and resistant to corrosion. Malleable Clips are a light duty wire rope clip and are not for anything overhead. As the name [malleable" indicates, it is a softer wire rope clip, thus a lighter duty option. They can be used for fences and other applications that do not sustain loads overhead. Overhead lifting vs. sustaining overhead loads The `overhead lifting` versus `sustaining overhead loads` can be confusing, but a good rule of thumb to ask is: [Is the object being moved or being held in place?" If it is being moved, then wire rope clips are not to be used. If it is being held in place, then the next question is: Is it above ground (suspended from ceiling, an awning, scaffolding, etc-) or will it be on a fence or on another object near the ground? If it is above ground, heavy duty drop forged is the best choice. If on a fence near the ground, malleable clips are acceptable. It`s important to note that wire rope clips diminish the working load limit of the wire rope to generally about 80% of its original strength. How to use wire rope clips The proper way to use wire rope clips can be remembered this way: [Never saddle a dead horse." The saddle of the clip is the piece that fits into the U bolt. The dead end of a wire rope is the end of the eye that contains the cut side. The U bolt should always be in contact with the dead end, while the saddle should be on the live end.

2020 04/22

- How To Use Our Machine Moving Skates ?If you are considering moving a storage container, a large machine, or a large awkward piece of equipment or furniture, then you will need one of our high quality machine moving skates. Machine moving skates make the transportation of a 55 tonne storage container easy work. To use machine moving skates simply get 4 low profile toe jacks to lift up the equipment that you wish to move. By using the toe jacks, jack the object high enough to slide the moving skate under all four corners. Slowly release the toe jacks when you are sure that the machine is in place. Attach the steering bars and move your machine to its new place. Because of the weight that you could be moving with cargo trolley , it is important that you chose high quality machine skates. Our ranges of machine moving skates all have polyurethane wheels. Polyurethane wheels have a higher load bearing capacity than rubber wheels and are oil and solvent resistant, they are also tear resistant, weather resistant, and resistant to extreme temperatures. On top of all these benefits, they also reduce the risk of damaging your work place floor.

2020 04/22

- What is the difference between a mechanical jack and a hydraulic jackWhat is the difference between a mechanical jack and a hydraulic jack ? With the number of jack types that are available, it is important to understand the difference between the two. Additionally, each type of jack offers its own benefits and drawbacks. Knowing which jack type to use involves understanding the differences in the two types of lifting devices. MECHANICAL JACKS In contrast to hydraulic jacks, mechanical jacks use only physical means of raising and lowering their loads. Using mechanical advantage, these jacks are commonly seen in the automotive industry for lifting vehicles and other loads. A common type of mechanical jack is known as a [screw jack." With the use of a motor, or a lever that is cranked by an operator, a screw uses the shape of its threads to raise or lower the jack. Depending on the type of jack, the screw itself may raise or lower the load, or a traveling nut does the raising while the screw turns in place. These jacks have many applications that include moving platforms on stages, changing settings on woodworking machinery, and adjustments of radio telescopes. Other applications also involve the use of mechanical jacks and they provide some advantage over hydraulic systems. Mechanical systems are normally self-locking. This means that when power is removed from the jack, the screw remains in the same position until power is reapplied. Self-locking properties make these jacks safer to use than hydraulic units, since operators need not worry about loss of power. Drawbacks of a mechanical system include the fact that they are not capable of lifting the same loads as hydraulic lifts. Additionally, levers that provide mechanical advantage for manual operations can only reach a certain length before bending and becoming useless. HYDRAULIC JACKS Jacks using hydraulic power operate on the phenomenon that fluids produce the same pressure at all points when contained in a closed system. With these types of jacks, a fluid is contained within a large and small container, both of which are linked by tubes. When a small amount of force is applied to the smaller tube, the pressure on the fluid increases. This means that, within the larger tube, the same amount of pressure per square inch is applied over a larger surface, resulting in an increased amount of force. With hydraulic jacks, smaller amounts of force are capable of lifting loads which would otherwise be impossible. The principals behind this type of jack was discovered back in the seventeenth century. Currently, it is used in a wide range of industries, including automotive, construction, fabrication and health care. Hydraulic jacks are commonly used to lift vehicles in order to conduct maintenance. While these jacks are capable of lifting heavier loads than mechanical jacks, they also have the drawback that the load will be lowered if the hydraulic power is removed from the jack. Operators must take care to ensure that hydraulic power remains in place while they are working with the jacks.

2020 04/22

- What are the Differences Between Types of Shackles?Shackles are manufactured in a wide variety of types, styles, sizes, and fabrications, and with so many different options available, choosing the right shackle for the job can be confusing. We`ve outlined some of the basic differences between the most common types of shackles. If you have any questions, contact one of our rigging product specialists on our sales team at + 86 1373021 9155. Anchor shackle/bow shackle vs.chain shackle/D-shackle Anchor shackle Bow shackles and anchor shackles are terms that are often used interchangeably, as both names refer to a shackle with a larger, rounded [O" shape look. However, a bow shackle typically has a larger, more defined bow area than an anchor shackle. The rounded design of anchor shackles and bow shackles allow them to take loads from many directions without developing significant side load. The larger loop shape of an anchor shackle or bow shackle does reduce its overall strength, but it is also able to handle a larger strap. Chain shackle Chain shackles are also known as D-shackles. Both refer to the [D" shape design. A d-shackle is narrower than a bow or anchor shackle and generally have a threaded pin or pin close. The smaller loop is designed to take high loads primarily in line. Side and racking loads may twist or bend a D or chain shackle. Both types of shackles are generally always available in galvanized metal and stainless steel, and all come with different pin options as well.

2020 04/22

- What`s the Difference Between Seat Belt Webbing and Polyester Webbing?A: Seat belt webbing is actually a polyester webbing but it`s slightly thinner and typically has a lower tensile strength than regular polyester webbing that`s usually used for ratchet straps, cam straps and winch straps. It obviously gets its name from its main use as webbing used for seat belts and other automotive restraints, but it can also be used for a variety of other applications: tents, tarps, bag straps, camping gear, boating accessories, garden and lawn equipment uses. Both regular polyester webbing and seatbelt webbing have excellent qualities for rugged use: it will not shrink, rot, mildew, or mold, because it absorbs very little water. It also stands up well to UV rays and many acids. You can see all of our cargo webbing here:http:// Webbing sling .round sling

2020 04/23

- What is mini car lifting crane ?Mini car lifting crane : mini car lifting crane also known as outdoor lifting machine, small crane, portable lifting machine, micro-lifting machine, electric crane and other small crane. This product is small, light weight, compact and easy to operate, 380V220V voltage are applicable, suitable for decoration, lifting operations, installation equipment, moving companies, factories, workshops, light industry, heavy industry, maintenance, warehousing, logistics and other lifting machine By the power device and the two parts of the bracket.

2017 12/07

- What is our advantages ?COMPANY ADVANTAGE: A>. We feel confidence that we can make you satisfied based on our earnest attitude . Everyone of our company must have some professional technology,then we can well control every step in the producing. B>. We exported the STEEL WIRE ROPE since 1995. Our products are welcomed in most country,for example,Russia,America, many countries in Europe. We are well know many local market demand, we can supply defferent standards(US,Europe,JIS,etc) products to various countries. C>.Our many advanced equipments and technicians are glad to do service for you. Our several professional technicians are with more than 20 years experience. They can cotrol the excellent quality for you.

2017 12/06

- What features of wire rope slingFeatures of wire rope sling : 1. Min breaking load is 6 times WLL 2. aluminum sleeve secured 3. Surface treatment: stainless,galvanized,ungalvanized,PVC/PP/PE/Nylon coated,hot dipped galvanized 4. Fully in line with European standards EN 13411-3, ISO, DIN, ASTM, JIS,MIL,EN12385, etc. 5. Specification of the steel wire rope: 6 X 19+FC/6 X 19+IWR/6X37+FC/6X37+IWR, 6x7+FC, 7X7, 7x37, 6x25, etc 6. Diameter: Ø4-30mm 7. Color: clear, black with the oil 8. Length: As requirements 9. Type: one end free + one end eye; both of end eye; with thimbles; without thimbles, or your requirements

2017 12/06

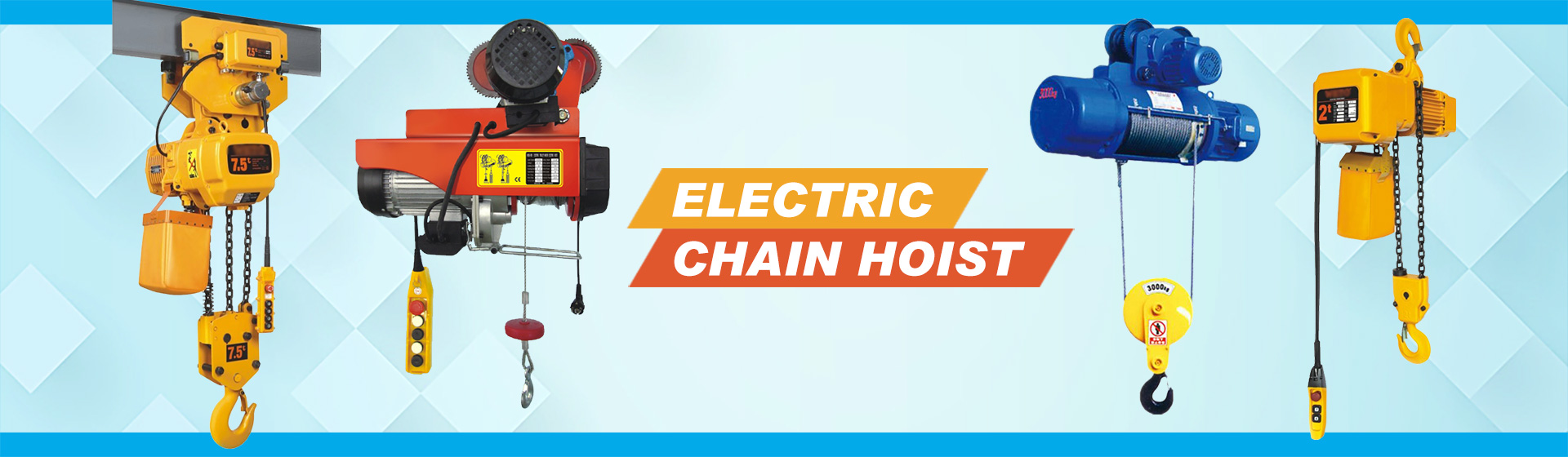

- What is the function of chain hoist ?Chain hoist is a device used for lifting or lowering a load by means of a drum or lift-wheel around which rope or chain wraps. A chain hoist may be manually operated pneumatically driven and use chain as its lifting medium. Most hoists couple to their loads using a lifting hook. Chain hoist is a portable lifting device easily operated by hand. Types of chain block is suitable for using in factories, agricultural production, and in wharf, docks and storage for fixing machines, lifting cargo, and loading and unloading goods. Chain block hoist can be attached to a trolley of any type as a travelling chain block. It is suitable to monorail overhead conveying system, hand travelling crane and jib crane.

2017 12/01

- Heavy Duty Warehouse Usage Machine Moving Skates Dolly Roller SkidsProduct Introduction: Moving Skates Carrying Tanks Transport Trolley is a kind of handling equipment that can replace roller as a handling tool. The use of large equipment, long-distance equipment, with crowbar or claw jacks, for the movement of heavy cargo, can save a lot of manpower and time. Advantage : Specifications: 6T, 8T, 12T, 15T, 18T, 24T, 50T, 100T, 200T Customized. Our engineer will give you advise and design if you need. Surface treatment: plastic spray, better than paint, will not be damaged easily. Improved turnable structure---Installation of balls, which makes the crushing wheels to turn more flexible and convenient. Material of wheels--PU, which is more wearable, durable and do little harm to the work place.

2021 10/12

- Lithium battery small 1.5ton 2Ton semi Electric Pallet TruckSmall dimension 1.5ton/2ton electric pallet truck, has smi electric and full electric two types. Lithium battery, convenient to recharge the battery and safe charging time. They are replacing manual pallet truck all the time. Widely used in logistic / Food/Textiles/Printing/Cold chain industries and supermarket, shopping mall, workshop and so on. PRODUCT SPECIFICATIONS 1 Model ET15MH ET20MH 2 Power type Battery Battery 3 Operation type Standing Standing 4 Loading capacity Q(kg) 2000 2500 5 Loading center C(mm) 600 600 6 Tyre type, front/rear solid PU solid PU 7 Wheel base y(mm) 1202/1272 1202/1272 8 Overall height h1(mm) 1280 1280 9 Max. Forks height h2(mm) 200 200 10 Overall length l1(mm) 1555/1625 1555/1625 11 Overall width b1/b2(mm) 540/680 540/680 12 Battery V/Ah 24/20 24/25 13 Drive motor 750w 750w 14 Service weight(inclue battery) kg 115/120 120/125

2021 09/30

- Retractable Lashing Strap Ratchet Tie Down StrapsThis towing strap is a nice rope with special processing procedure. Towing strap can absorb towing jerks and reduce the vibration of two cars to the lowest during towing. The fluorsent color makes it safer while being used at night. The towing strap with safety latch can prevent it from falling off the car and make it easier to take off or put on. Product overview of tow strap 1.Raw material :100% high-quality and high strength dacron (polyester) 2.Provided by hook and shackles 3.Elongation <7% 4.Length of product :4-8M or more 5.Band width:5-10cm or more 6.Breaking strength:1-20T 7.Colour:made according to the customer request Specifications of ratchet strap Width 25mm 35mm 50mm 75mm 100mm Break Strength 600kg,750kg, 800kg,1500kg 900kg,2000kg, 3000kg 2000kg,4000kg, 5000kg 6800kg, 7250kg, 7350kg Strap length 4m,6m,8m, 9m, 10m, 12m etc Strap color Orange,red, blue,yellow,black,white,etc Hook type Double J hook, Flat hook, S hook, Swivel hook,etc To American market Width 1" 1.5" 2" 3" 4" Break Strength 1650lbs, 1760lbs 4400lbs, 6600lbs 4400lbs, 6600lbs, 10000lbs, 11000lbs 15000lbs,16000lbs,16200lbs Strap length 27inches, 30inches etc Strap color Orange, red, blue, yellow, black, white etc Hook type Double J hook, Flat hook, S hook, Swivel hook etc

2021 08/12

- Semi Electric Hydraulic Walkie Stacker ForkliftAdvantages: * With hydraulic leveler control lifting and lowering, speed is adjustable. * Explosion-proof valve applied in the cylinder reventsinjuries in case of hydraulicpump failure. * Brand-new configuration: adopted 1.5kw hydraulic pump (manual descending with controllable speed) * With large storage battery. * Steering mechanism driven by chains requires small steering force to convenient operations. * Foot brake is more prompt, convenient and labor saving. * Optional forks: stationary forks, adjustable forks, forged forks. * adopted plate chains with high strength. Ensure safety and stability.

2021 07/20

- 2 ton Hydraulic Folding Shop Crane Engine Hoist2 ton Hydraulic Folding Shop Crane Engine Hoist 1. Strong, durable, versatile, and real save the space 2. Allows for maximum lifting power at a minimum of shop space 3. Easy to move an engine from car to work space in seconds 4. 4-hole position reinforced boom enables 4 different lengths and 4 load capacities 5. Hydraulics are powered with a high quality oil, which offers better corrosion resistance and high/low temperature flexibility, allowing the unit to operate at temperatures between 40 degrees F and 105 degrees F. 6. High quality large diameter hydraulic steel cylinder unit results in lower oil pressure needed to move the load, which helps to reduce wear and extend service life.

2021 07/16

- 5 ton 1ton Electric Travelling Hoist with Wire RopeElectric Hoist Features: *Electric wire rope hoist is a type of material handling equipment, installed on a single beam crane, linear curve strander beams or it can be used at the hoisting mechanism of double beam crane, gantry crane, linear crane for material handling by industrial and mining enterprises, railways, and warehouses, etc. *Individual needs require specific solutions. That is why we developed the CD/MD Series, HB Explosion Proof Series, YH Metallurgy Series European Series. You can benefit from ground-breaking flexibility in all types of applications: from stationary installations to crane systems. For the first time, a rope hoist can be built either in a C-design or co-axial design utilising one basic technology. *The lifting capacity of CD/MD wire rope hoist is 0,5 to 32 ton and the working class is M3 and M4.

2021 07/14

Email to this supplier